In modern industrial production, packaging plays a critical role in ensuring product quality, ease of transportation, and consumer safety. Various packaging machines have been developed to meet the diverse requirements of different industries, including food, pharmaceuticals, chemicals, and consumer goods. Among these, the screw packing machine is a specialized type of equipment designed for precise volumetric or weight-based filling of granular, powdered, or small-sized products. Understanding how it differs from other packaging machines is essential for manufacturers seeking efficiency, accuracy, and versatility in their packaging processes.

This article explores the differences between screw packing machines and other common types of packaging machines, focusing on mechanism, product compatibility, accuracy, speed, maintenance, and cost-effectiveness.

What is a Screw Packing Machine?

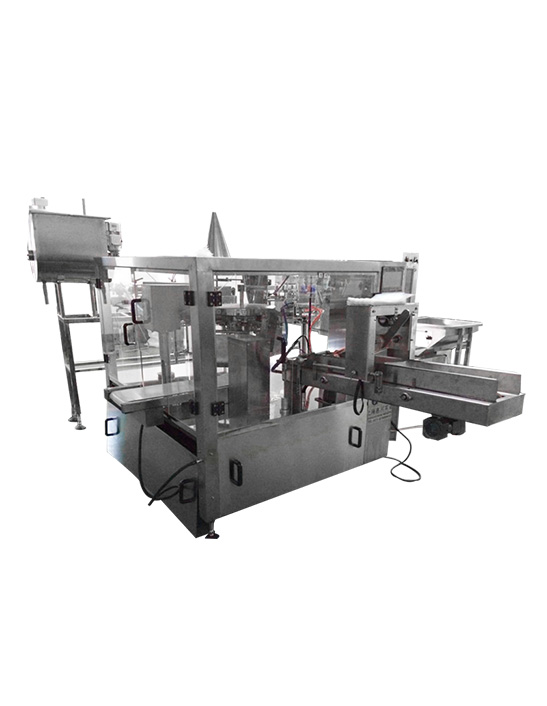

A screw packing machine is an automated or semi-automated device that uses a screw feeder to measure and dispense a specific quantity of a product into packaging containers such as pouches, bottles, jars, or cans. The screw mechanism rotates to transport a fixed volume of product from the hopper to the packaging unit. Depending on the design, screw packing machines can be single-head or multi-head, allowing for simultaneous filling of multiple packages.

Key features of screw packing machines include:

- Precise volumetric or weight-based filling using adjustable screw sizes or rotation speeds.

- Ability to handle powders, granules, seeds, and small solids with minimal spillage.

- Flexible integration with conveyors, sealing machines, and labeling equipment.

- Automation options ranging from semi-automatic to fully automatic operation.

Mechanism and Operation Differences

1. Screw Packing Machine

The defining characteristic of a screw packing machine is its auger screw mechanism, which provides controlled product flow and precise measurement. Products are loaded into a hopper, and a rotating screw transports a set quantity into each package.

Key Operational Advantages:

- High measurement accuracy for powders and granules.

- Minimal product degradation due to gentle handling.

- Adjustable screw size and rotation speed allow flexibility for different product densities and package sizes.

2. Piston Filling Machine

- Mechanism: Uses a piston to draw and push liquid or semi-liquid products into containers.

- Key Difference: Ideal for liquids, creams, or viscous products; not suitable for powders or granular solids. Screw packing machines, in contrast, are optimized for dry materials.

3. Volumetric Cup Filling Machine

- Mechanism: Uses a cup or compartment of fixed volume to scoop and deposit product.

- Key Difference: While volumetric cup fillers can handle powders, they are less adjustable for different product densities and may require manual calibration. Screw packing machines offer more precise control and automation.

4. Weighing or Multihead Weigher Machine

- Mechanism: Weighing machines use load cells to measure exact product weight before dispensing.

- Key Difference: Highly accurate but often more complex and expensive than screw packing machines. Screw fillers are simpler, faster for medium-accuracy applications, and easier to maintain.

5. Liquid Filling Machine

- Mechanism: Uses pumps, gravity, or vacuum systems to fill liquids into bottles or pouches.

- Key Difference: Unsuitable for granular or powdered materials; screw packing machines handle dry products efficiently.

Summary: The screw packing machine’s mechanical auger system is specifically suited for granular and powdered products, whereas other machines are optimized for liquids, semi-liquids, or high-precision weighing applications.

Product Compatibility

Screw packing machines are highly versatile but excel with dry, free-flowing products, such as:

- Powdered chemicals, flour, sugar, and spices.

- Granular food products like rice, seeds, coffee, and snacks.

- Small solid items such as pills, capsules, or hardware components.

Comparison with Other Machines:

- Piston or liquid fillers cannot handle solid or granular products effectively.

- Volumetric cup fillers may struggle with sticky or uneven-density powders.

- Multihead weighers excel in accuracy but are costlier for small-scale or medium-speed operations.

This specialization makes screw packing machines ideal for industries where dry product packaging is critical, including food, pharmaceuticals, and agriculture.

Accuracy and Measurement

One of the main advantages of screw packing machines is consistent and precise measurement, achieved through:

- Adjustable screw diameter and pitch.

- Variable rotation speed controlled by motors or PLC systems.

- Calibration mechanisms for different product densities.

Other Packaging Machines:

- Piston fillers provide accurate volume for liquids but may vary with viscosity changes.

- Cup fillers are limited by fixed compartment size and may require frequent adjustment for density differences.

- Multihead weighers are highly precise but involve complex calibration and maintenance.

Key Difference: Screw packing machines offer a balance of accuracy and simplicity for powdered and granular products, with less complexity and lower maintenance compared to weighing machines.

Speed and Efficiency

Screw packing machines are designed for high-speed production, especially with automatic models:

- Single-head machines: Suitable for small to medium batches.

- Multi-head machines: Can fill multiple packages simultaneously, increasing throughput.

Comparison:

- Piston and liquid filling machines can operate at high speed for liquids but are unsuitable for solids.

- Multihead weighers offer high speed for varied product sizes but involve higher operational costs.

- Cup fillers are moderate in speed but less adaptable for continuous production of varied products.

Key Advantage: Screw packing machines provide an optimal combination of speed and precision for dry product packaging.

Maintenance and Operational Costs

Screw Packing Machines

- Simple design with minimal moving parts in contact with the product.

- Easy to clean and maintain, especially in food or pharmaceutical applications.

- Spare parts are readily available and inexpensive.

Other Machines

- Multihead weighers require careful calibration and regular maintenance of load cells.

- Liquid or piston fillers need pump maintenance and frequent cleaning to prevent clogging.

- Cup fillers may require more frequent adjustments when product properties change.

Key Difference: Screw packing machines are cost-effective for maintenance and longevity, making them suitable for small to medium-scale operations without specialized technical support.

Integration and Automation

Modern screw packing machines can integrate with:

- Conveyors for automated product feeding.

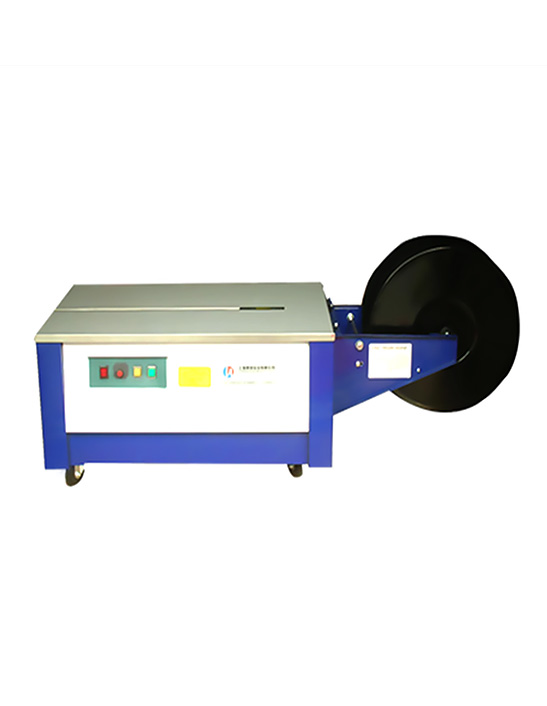

- Sealing and capping machines for complete packaging lines.

- Labeling systems to streamline production.

- PLC controls for monitoring speed, rotation, and output.

Comparison: While other packaging machines also support integration, screw packing machines offer simpler automation setups for dry products, requiring less technical expertise than high-end multihead weighing systems.

Applications Across Industries

- Food Industry: Sugar, flour, spices, snacks, coffee, rice.

- Pharmaceutical Industry: Powdered medicines, capsules, supplements.

- Chemical Industry: Dry chemicals, detergents, fertilizers, salts.

- Hardware and Manufacturing: Small screws, nuts, beads, and other granular items.

Other packaging machines are better suited to liquid, semi-liquid, or irregularly shaped products, highlighting the unique niche that screw packing machines fill.

Advantages and Limitations

Advantages of Screw Packing Machines

- Accurate volumetric or weight-based filling.

- High speed for granular and powdered products.

- Simple maintenance and operation.

- Compact footprint for small-scale production.

- Flexible integration with existing production lines.

Limitations

- Not suitable for liquids or highly viscous materials.

- Less precise than multihead weighers for products requiring strict weight control.

- May struggle with very sticky or clumping powders without additional anti-caking measures.

Conclusion

Screw packing machines differ significantly from other types of packaging machines in mechanism, product compatibility, accuracy, speed, and maintenance requirements. While piston, liquid, cup, and multihead weighing machines excel in their respective areas, the screw packing machine is specifically optimized for dry, granular, and powdered products, providing a balance of efficiency, precision, and cost-effectiveness.

Manufacturers who package powders, granules, seeds, or small solids benefit from screw packing machines due to their simplicity, adaptability, and ability to integrate with automated production lines. Understanding these differences allows businesses to select the most appropriate packaging technology, ensuring product quality, operational efficiency, and cost savings.

英语

英语 西班牙语

西班牙语 简体中文

简体中文