Introduction: Why Industry Fit Matters for Large Vertical Packing Machines

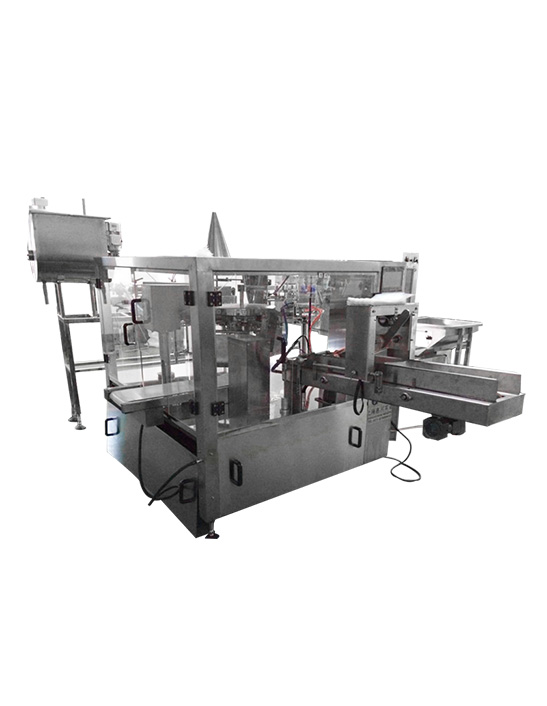

Large vertical packing machines (LVPMs) are engineered to form, fill, and seal bags or pouches in a vertical orientation, handling high-throughput bulk and semi-bulk products. Choosing the right industry application is not just about volume — it’s about product characteristics, regulatory demands, packaging formats, hygiene requirements, and integration with upstream feeders. This article examines the industries that gain the most measurable benefits from LVPMs and gives practical guidance on selecting, customizing, and implementing these systems to maximize uptime and return on investment (ROI).

Food & Beverage: High-Volume Powders, Granules, and Snack Packaging

The food and beverage sector is one of the largest users of LVPMs. Typical products include rice, sugar, flour, dried legumes, pet food kibble, snacks, and powdered mixes. These machines handle different bag types — pillow, gusseted, valve (for coffee), and doypack-style pouches — and can integrate with weighers, multihead scales, or volumetric fillers.

Key benefits for food processors

LVPMs deliver high throughput (often measured in bags per minute), consistent portioning, and reduced contamination risk when equipped with stainless-steel contact surfaces and CIP-friendly designs. Options like nitrogen flushing, gas barrier film handling, and automated metal detection can be added for shelf-life and safety compliance.

- Supports a variety of bag sizes and materials suitable for food-grade packaging.

- Easily integrates with multihead weighers for accurate portion control.

- Sanitary construction reduces downtime for cleaning and inspection.

Agriculture and Seed: Bulk Bags, Seed, Fertilizer Pellets

Agricultural products like seeds, feed pellets, and some dry fertilizers require robust LVPMs capable of handling abrasive and dusty materials. Machines for this industry often include heavy-duty auger fillers, dust extraction interfaces, and reinforced infeed conveyors to withstand continuous operation in tougher environments.

Industry-specific considerations

Durability, dust control, and simple maintenance are critical. Systems may be fitted with bulk bag filling stations (FIBC) or small bag form-fill-seal heads depending on packaging scale. Integration with scale-based batching and traceability systems is often required for quality and inventory control.

Chemical and Mineral Processing: Powders and Granulars

Chemicals, powdered minerals, and industrial granules benefit from LVPMs that offer accurate dosing and containment. For hazardous or irritant powders, LVPMs can be enclosed with negative-pressure dust control, glove ports, and automatic sealers to protect workers and the environment.

Safe handling and compliance

Key features include explosion-proof components for combustible dust, inerting systems for sensitive chemistries, and materials compatibility to avoid corrosion. Accurate volumetric or gravimetric dosing is necessary to meet formulation tolerances and regulatory labeling requirements.

Construction Materials: Sand, Cement, and Aggregates

Heavy, dense products such as cement, sand, and mortar mixes require LVPMs designed for rugged loading and abrasion resistance. These machines often operate at slower bag-per-minute rates but with high bag weights (10–50 kg or more). Auger or belt dosing combined with reinforced bag holders and discharge spouts are common.

Design adaptations for heavy materials

Reinforced frames, easily replaceable wear liners, and strong bag grips reduce downtime. Dust suppression and integrated weighing ensure accuracy and cleaner workplaces, while palletizing interfaces streamline downstream logistics.

Pharmaceuticals and Nutraceuticals: When Hygiene and Precision Matter

Although pharmaceuticals often require small-dose packaging, certain nutraceutical powders, bulk supplements, and intermediate powders are efficiently packaged with LVPMs. For this sector, strict GMP compliance, traceability, and contamination control dictate machine choice.

Critical features for regulated products

Pharma-grade LVPMs should include validated cleaning procedures, stainless steel 316 contact parts, HEPA-filtered enclosures, and electronic batch records integration. Accuracy is driven by high-precision loss-in-weight feeders or multihead weighers.

Pet Care and Animal Feed: Versatile Bagging and Bulk Options

Pet food and animal feed range from small kibble to large 25 kg/50 lb bags. LVPMs are ideal because they handle many bag forms and fill types, from volumetric cup fillers for dry kibble to auger systems for pellets and powders. Features such as zipper insertion, valve bags, and window film options add retail appeal.

How to Match Machine Features to Industry Needs

Selecting the correct LVPM involves matching product characteristics, desired bag style, throughput targets, and environmental or regulatory constraints. Below is a compact table to compare industry needs and recommended machine capabilities.

| Industry |

Typical Products |

Preferred Bag Types |

Key Machine Features |

| Food & Beverage |

Rice, flour, snacks, powders |

Pillow, gusset, valve |

Multihead weighers, nitrogen flush, stainless contact |

| Agriculture |

Seeds, feed pellets |

Open-mouth sacks, small bags |

Auger fillers, dust control, heavy-duty construction |

| Chemicals |

Powders, granules |

Valve, paper-plastic laminates |

Enclosures, inerting, explosion-proof options |

| Construction |

Cement, sand, mortar |

Open-mouth heavy sacks |

Reinforced frames, high-capacity augers |

| Pharma/Nutraceutical |

Bulk powders, supplements |

Pouches, sachets, small bags |

GMP constructions, HEPA, validated dosing |

Operational Tips: Maximize Uptime and ROI

To ensure the LVPM delivers value, focus on integration, operator training, and preventative maintenance. Smooth feed from upstream equipment (silos, conveyors, mixers) prevents surges that cause rejects. Implement changeover protocols to reduce downtime when switching bag sizes or materials.

- Use modular tooling to enable fast bag-size changeovers and reduce setup time.

- Standardize spare parts inventory for critical wear items like belts, seals, and cutter blades.

- Schedule regular calibration of weighing systems to maintain accuracy and reduce rework.

Conclusion: Choosing LVPMs for Real Business Impact

Large vertical packing machines bring measurable advantages where high-volume, consistent, and hygienic packaging is needed. Food, agriculture, chemical, construction, pet care, and select pharmaceutical/nutraceutical applications are the industries that typically see the best fit. The right machine configuration—filler type, sealing head, sanitary features, and controls—combined with good operational practices results in higher throughput, lower labor costs, and predictable ROI. When evaluating options, prioritize compatibility with your product characteristics and downstream processes to ensure the LVPM becomes a productive and long-lived asset.

英语

英语 西班牙语

西班牙语 简体中文

简体中文