In today’s fast-paced manufacturing and packaging industries, efficiency, accuracy, and automation are critical. One machine that has significantly transformed the packaging process is the screw packing machine. Often overlooked by those outside the industry, this piece of equipment is essential for precise, high-speed, and cost-effective packaging of granular, powdered, and small particulate products. From food and pharmaceuticals to chemicals and hardware components, screw packing machines play a pivotal role in ensuring operational excellence.

This article delves into what a screw packing machine is, how it works, its types, applications, benefits, operational considerations, and emerging trends, highlighting why it has become indispensable in modern packaging processes.

What Is a Screw Packing Machine?

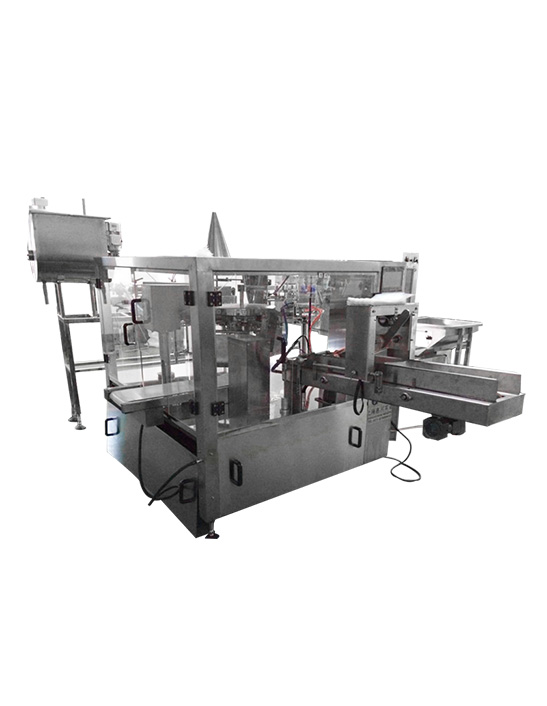

A screw packing machine is a specialized device designed to automatically measure, fill, and seal granular or powdered products into pre-determined containers, such as bags, pouches, or jars. The machine uses a screw feeder system to deliver consistent and precise quantities of material to each package, ensuring accuracy and minimizing waste.

Unlike manual or semi-automatic methods, screw packing machines offer high-speed, continuous, and repeatable packaging, making them ideal for industrial-scale operations.

How Does a Screw Packing Machine Work?

The operation of a screw packing machine involves several coordinated steps:

Product Feeding – Bulk material is fed into a hopper or storage container.

Screw Conveying – A rotating screw or auger moves the material toward the dispensing mechanism.

Volume Measurement – The screw mechanism measures the exact amount of product for each package. Adjustable screws or augers allow customization of the portion size.

Filling – The machine deposits the measured product into containers such as bags, jars, or sachets.

Sealing and Packaging – Depending on the model, the machine may automatically seal the package with heat, adhesive, or mechanical closures.

Output and Collection – Finished packages are conveyed for labeling, storage, or shipment.

This process reduces human error, ensures consistency, and significantly increases packaging speed.

Types of Screw Packing Machines

Screw packing machines come in various configurations to accommodate different products, packaging formats, and production scales:

1. Volumetric Screw Filling Machines

Volumetric machines measure material by volume using the screw rotation. They are ideal for dry powders, grains, and granular products, offering fast and reliable operation.

2. Auger Filling Machines

Auger fillers are designed specifically for powdered products. They use a rotating auger to dispense precise portions into containers. Auger fillers are highly accurate and commonly used in the food, pharmaceutical, and chemical industries.

3. Multi-Head Screw Packing Machines

Multi-head machines have several screw feeders working simultaneously, enabling higher throughput for large-scale production lines. They are suitable for high-speed packaging requirements.

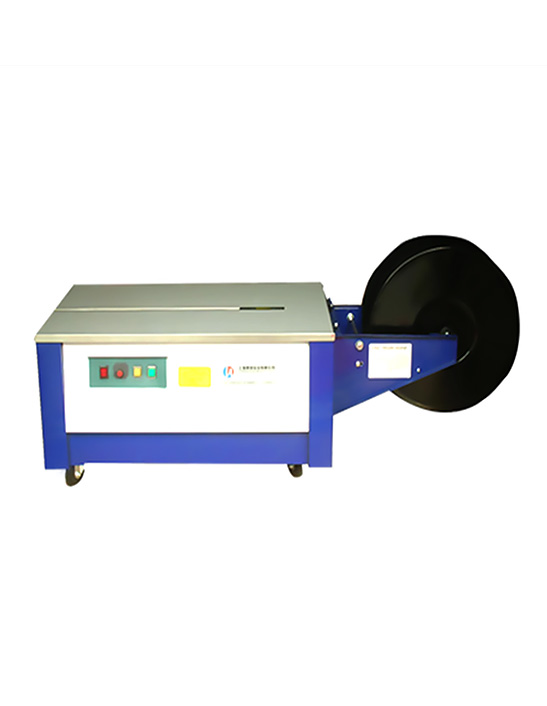

4. Semi-Automatic Screw Packing Machines

These machines require some manual intervention, such as loading containers or starting the machine, but still offer consistent portioning and faster operation than fully manual processes.

5. Fully Automatic Screw Packing Machines

Fully automated machines integrate feeding, portioning, filling, sealing, and conveying. They provide maximum efficiency, minimal human intervention, and are ideal for industrial operations with high production demands.

Applications of Screw Packing Machines

Screw packing machines are versatile and used in a variety of industries for packaging powdered or granular products. Common applications include:

1. Food Industry

Spices and Seasonings – Accurate portioning of powders, salt, sugar, and seasonings into sachets or jars.

Coffee and Tea – Packaging ground coffee, instant coffee, or tea leaves into pre-measured packs.

Grains and Seeds – Filling rice, lentils, nuts, or seeds into bags.

2. Pharmaceutical Industry

Medicinal Powders – Filling vitamins, supplements, and powdered medications into bottles or sachets.

Precise Dosage Packaging – Ensuring accurate dosing for safe consumption.

3. Chemical Industry

Detergents and Powders – Filling powdered chemicals into bags or containers for consumer or industrial use.

Fertilizers – Accurate portioning of granular fertilizers into bags.

4. Hardware and Industrial Components

Small Parts – Packaging screws, nuts, bolts, and other hardware components.

5. Cosmetics and Personal Care

Powdered Products – Packaging talcum powder, face powders, or bath salts into sachets or jars.

Benefits of Using a Screw Packing Machine

1. High Accuracy

Screw packing machines ensure precise portioning, minimizing overfilling or underfilling. This accuracy reduces material waste and ensures consistency across batches.

2. Increased Efficiency

Automated feeding, portioning, and packaging significantly reduce production time, enabling higher throughput compared to manual methods.

3. Cost Savings

Reduced labor requirements, minimized material wastage, and faster production speeds translate to lower operational costs.

4. Versatility

Screw packing machines can handle various materials, including powders, granules, seeds, and small components, making them suitable for multiple industries.

5. Improved Hygiene and Safety

Automated handling reduces direct human contact with the product, ensuring higher hygiene standards, particularly in food and pharmaceutical applications.

6. Customizable Packaging

Adjustable screws and augers allow operators to package different weights, volumes, and container sizes, enhancing flexibility.

Operational Considerations

To achieve optimal performance, operators must consider several factors when using a screw packing machine:

Material Characteristics – Flowability, particle size, moisture content, and density affect machine settings.

Screw Design – Proper auger or screw selection ensures consistent portioning and prevents clogging.

Speed Settings – Adjusting rotational speed impacts accuracy and throughput.

Maintenance – Regular cleaning, lubrication, and inspection prevent downtime and ensure machine longevity.

Calibration – Periodic calibration ensures consistent weight and volume measurements.

Container Compatibility – Ensure the machine is compatible with bag, jar, or pouch dimensions.

Challenges and Solutions

While screw packing machines are highly efficient, they face certain challenges:

Powder Clumping – Hygroscopic or sticky powders can clog the screw. Solutions include anti-caking agents or vibration-assisted feeding.

Inconsistent Flow – Uneven material density may cause inaccuracies, mitigated through proper screw selection and hopper design.

Maintenance Requirements – Dust and residue buildup require regular cleaning to maintain precision.

Adaptation to Multiple Products – Changing product types may require adjustments to screws, hoppers, and settings.

By addressing these challenges with proper training, maintenance, and equipment selection, manufacturers can ensure reliable operation.

Emerging Trends in Screw Packing Machines

1. Automation and Smart Technology

Integration with PLC systems, sensors, and IoT allows real-time monitoring, fault detection, and remote control of packaging lines.

2. Multi-Function Machines

Modern machines combine screw feeding, weighing, and sealing in a single system to reduce footprint and streamline production.

3. High-Speed and Multi-Head Systems

Multi-head screw packers increase output capacity, meeting high-volume production demands efficiently.

4. Sanitary and Food-Grade Designs

Stainless steel construction, dust-free operation, and easy cleaning enhance compliance with food and pharmaceutical safety standards.

5. Eco-Friendly Packaging

Some machines are designed to handle biodegradable or recyclable packaging materials, supporting sustainability initiatives.

Why Screw Packing Machines Are Essential

Precision Packaging – They provide consistent weight and volume, ensuring customer satisfaction and regulatory compliance.

Operational Efficiency – Automation accelerates production and reduces labor costs.

Versatility Across Industries – Suitable for food, pharmaceutical, chemical, and hardware packaging.

Enhanced Safety and Hygiene – Minimized human contact improves product safety.

Adaptability to Modern Packaging Needs – Compatible with various packaging types, including pouches, jars, and sachets.

Conclusion

A screw packing machine is a cornerstone of modern packaging operations. From granular food products to powdered pharmaceuticals and industrial components, these machines ensure precise, fast, and safe packaging. They not only optimize productivity but also reduce waste, lower operational costs, and maintain high hygiene standards.

With ongoing technological advancements, including automation, multi-head systems, and smart integration, screw packing machines are evolving to meet the growing demands of high-speed, efficient, and environmentally responsible packaging. For manufacturers seeking to improve accuracy, productivity, and product safety, investing in a screw packing machine is no longer optional—it is a necessity.

英语

英语 西班牙语

西班牙语 简体中文

简体中文