A

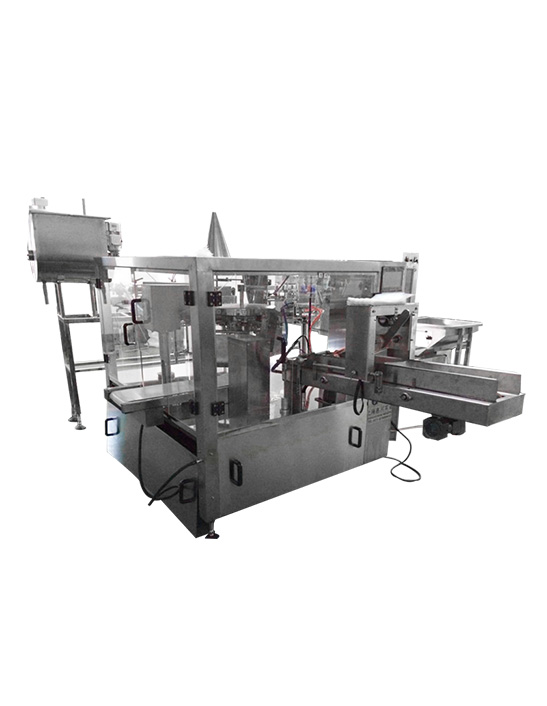

sponge packing machine, also known as a sponge packaging machine or a sponge sealing machine, is a device used to package sponges in a standardized and efficient manner. It is commonly used in manufacturing and packaging facilities that produce sponges for various applications, such as cleaning, cosmetics, or medical purposes.

The primary purpose of a sponge packing machine is to wrap individual sponges in a protective material, often plastic film or shrink wrap, and seal the packaging to ensure hygiene and product integrity. The machine automates the packaging process, reducing the need for manual labor and increasing productivity.

Here is a general overview of how a typical sponge packing machine works:

Sponge feeding: The machine is equipped with a sponge feeding system that supplies individual sponges to the packaging area. This can be done manually or using an automated conveyor system.

Packaging material preparation: The machine prepares the packaging material, such as plastic film or shrink wrap, by unwinding it from a roll. The material is cut to the appropriate size to accommodate the sponge.

Sponge insertion: The machine places the sponge onto the prepared packaging material. This can be done through mechanical arms or suction devices, depending on the machine's design.

Wrapping and sealing: The packaging material is wrapped around the sponge, forming a protective cover. The machine applies heat or pressure to seal the packaging material, ensuring it remains securely closed.

Trimming and cutting: Once the packaging material is sealed, excess material may be trimmed or cut off to create a neat and presentable package.

Product ejection: The finished packaged sponges are ejected from the machine, ready for further processing, labeling, or distribution.

Sponge packing machines can be customized based on the specific requirements of the manufacturer or the type of sponges being packaged. They may incorporate additional features such as labeling systems, batch coding, or quality control mechanisms to ensure consistent packaging standards.

By utilizing a sponge packing machine, manufacturers can improve the efficiency of their production process, reduce labor costs, maintain product hygiene, and enhance the overall presentation of their sponges for customers.

英语

英语 西班牙语

西班牙语 简体中文

简体中文