Industry News

Home /

News /

Industry News /

What is the difference between the two types of edible oil filling machines?

What is the difference between the two types of edible oil filling machines?

10-Jan-2022

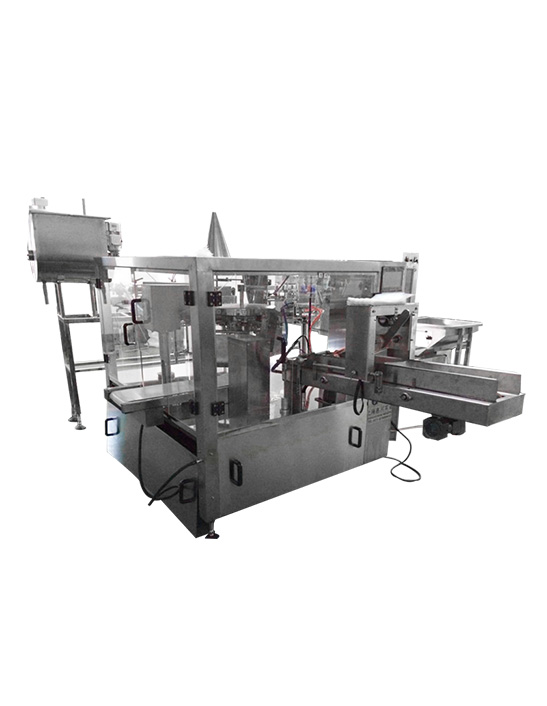

Edible oil filling machines generally use flow meter filling. Flow meter filling means that the computer automatically tracks the temperature and density of the oil and adjusts the oil delivery at any time, so that the quality of the oil can reduce errors caused by changes in temperature and density. The accuracy is high. Both use constant volume filling and constant quality filling two measuring methods.As an indispensable nutrient in people's lives, edible oil provides a variety of nutrients to the human body. Peanut oil, soybean oil, blended oil and other edible oils appear on the dining table, and the edible oil filling machine is a professional equipment for filling edible oil. Therefore, the edible oil filling machine also has a decisive weight.Nowadays, the technology of edible oil filling machines is constantly improving. The filling method mostly uses flowmeter filling. Flowmeter filling is a computer that automatically tracks changes in oil temperature and density to adjust the oil delivery at any time. The edible oil filling machine uses The oil quality reduces errors caused by changes in temperature and density, and the measurement accuracy is higher. Both use constant volume filling and constant quality filling two measuring methods.According to the degree of automation, edible oil filling machines can be divided into semi-automatic filling machines and fully automatic filling machines. These two filling methods have their own characteristics. Now let us see the differences!

1. Semi-automatic edible oil filling machineSemi-automatic filling machines generally have a foot switch, quantitative → put the barrel → start by stepping on the foot → drop the oil nozzle → fill → oil nozzle rise → vacuum suction → put down a group of empty barrels.The semi-automatic filling machine is divided into single-head and double-head, with a single-head filling capacity of 120 barrels per hour (calculated as 5 liters). Double-head small package filling capacity: 360 barrels/hour (calculated as 5 liters).2. Fully automatic edible oil filling machineAutomatic edible oil filling machine process: manual quantification→manual bottle placement→automatically detect the drop of the nozzle position of the bottle mouth→automatic filling→automatic transmission→manual capping→automatic capping→automatic coding→conveyor belt warehouse (this process only requires There are two manual operations of manual bottle placement and manual cap placement, and unmanned filling can also be realized.

1. Semi-automatic edible oil filling machineSemi-automatic filling machines generally have a foot switch, quantitative → put the barrel → start by stepping on the foot → drop the oil nozzle → fill → oil nozzle rise → vacuum suction → put down a group of empty barrels.The semi-automatic filling machine is divided into single-head and double-head, with a single-head filling capacity of 120 barrels per hour (calculated as 5 liters). Double-head small package filling capacity: 360 barrels/hour (calculated as 5 liters).2. Fully automatic edible oil filling machineAutomatic edible oil filling machine process: manual quantification→manual bottle placement→automatically detect the drop of the nozzle position of the bottle mouth→automatic filling→automatic transmission→manual capping→automatic capping→automatic coding→conveyor belt warehouse (this process only requires There are two manual operations of manual bottle placement and manual cap placement, and unmanned filling can also be realized.

https://www.china-packmachine.com/