In today’s fastpaced, efficiencydriven manufacturing and packaging world, businesses are constantly searching for ways to streamline operations, reduce waste, and improve output without compromising product quality. Among the many technological advancements shaping the packaging industry, the Horizontal Packing Machine has emerged as a gamechanging solution. But what makes this machine such a smart investment—and why are so many industries adopting it?

In this article, we’ll explore the key benefits, applications, working principles, and buying considerations surrounding horizontal packing machines. Whether you run a food processing unit, a pharmaceutical plant, or a consumer goods company, understanding how horizontal packing machines work—and why they’re worth your attention—can help you stay ahead in a competitive marketplace.

What Is a Horizontal Packing Machine?

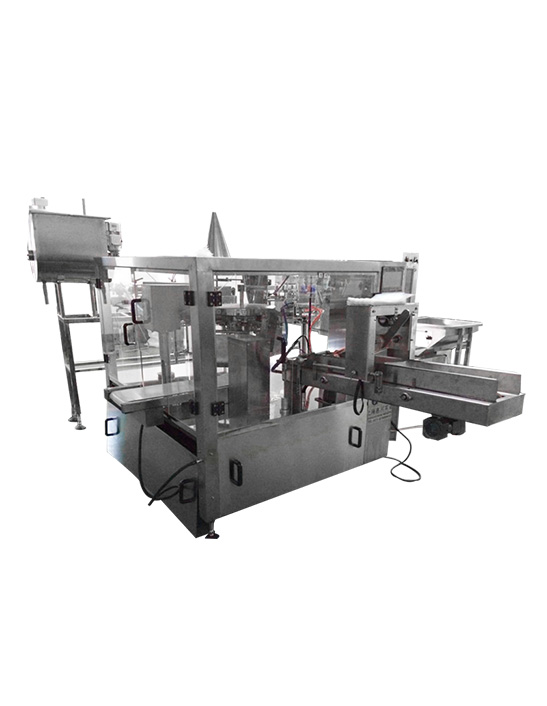

A Horizontal Packing Machine also known as a Horizontal Form Fill Seal (HFFS) machine, is an automatic packaging solution that forms, fills, and seals products horizontally. Products are typically fed into the machine on a conveyor belt, and the machine wraps them using flexible packaging material such as plastic film, foil, or laminate.

The horizontal flow of the product makes this machine ideal for items that are solid, regular in shape, or easily handled mechanically—think of biscuits, soap bars, medical devices, or even hardware.

How Does It Work?

Here’s a simplified breakdown of how a horizontal packing machine operates:

1. Film Feeding: A roll of film is loaded onto the machine, which feeds the film into the forming section.

2. Product Infeed: Products are placed (manually or automatically) onto an infeed conveyor.

3. Forming and Wrapping: The machine folds the film around the product, forming a tube or pouch horizontally.

4. Sealing: The machine heatseals the film, first along the sides and then at both ends.

5. Cutting: The wrapped and sealed product is cut to individual units and discharged for further processing or boxing.

This continuous flow operation ensures highspeed packaging with consistent quality.

Key Advantages of Horizontal Packing Machines

1. HighSpeed Production

Horizontal packing machines can process hundreds of units per minute, depending on the product and machine type. This makes them ideal for highvolume operations looking to boost output.

2. Versatility in Packaging

They can handle a variety of products and shapes—single items, multipacks, pillow packs, or gusseted pouches. This versatility makes them suitable for multiple industries, from snacks and confectionery to cosmetics and electronics.

3. Compact and Efficient Design

Despite their power, most horizontal machines are spaceefficient, often incorporating compact modular designs that fit neatly into existing production lines.

4. Reduced Labor Costs

With automated feeding, forming, filling, and sealing, these machines drastically reduce the need for manual labor. Fewer operators are needed to run highspeed lines, saving operational costs in the long term.

5. Superior Packaging Quality

Horizontal packing machines produce consistent seals and tightly wrapped packages that improve shelf life, protect products from contamination, and create a professional appearance that enhances brand value.

6. Waste Reduction

With precise control over material usage, these machines help reduce film waste, making your operation more sustainable and costeffective.

7. Customization and Integration

Modern machines come equipped with touchscreen PLC controls, sensors, and smart diagnostics. They can also be integrated with printers, labelers, or metal detectors, turning your packaging line into a smart factory system.

Industries That Benefit from Horizontal Packing Machines

1. Food and Beverage

Biscuits, cakes, chocolate bars, readytoeat meals, and frozen items are all perfect candidates.

Horizontal machines ensure hygienic, tamperproof, and shelfstable packaging.

2. Pharmaceutical and Medical

Pills, tablets, syringes, and diagnostic kits can be packed securely with minimal human contact, reducing contamination risk.

3. Cosmetics and Personal Care

Products like soap bars, facial wipes, and disposable razors benefit from neat, attractive packaging.

4. Consumer Electronics and Hardware

Batteries, small tools, and cables are easy to handle with horizontal flow wrappers.

5. Household Goods

Items like sponges, tissues, and cleaning wipes are quickly and cleanly packed.

Things to Consider Before Buying

Investing in a horizontal packing machine is a big step, and you should consider the following factors before purchasing:

Product Type: Is your product compatible with horizontal wrapping? Will the machine handle its size, shape, and texture?

Speed Requirements: Estimate your throughput needs to choose a machine that won’t underperform or waste resources.

Packaging Material: Ensure compatibility with the materials you use—whether it's polyethylene, polypropylene, or biodegradable film.

Automation Level: Decide if you need a semiautomatic or fully automatic system, depending on your staffing and line integration.

Budget and ROI: Analyze not just the upfront cost, but longterm savings in labor, material waste, and productivity.

Service and Support: Choose a manufacturer with a strong reputation for aftersales service, spare parts availability, and technical support.

Future Trends in Horizontal Packaging Technology

As industries lean into smart automation and sustainability, horizontal packing machines are evolving to meet new demands:

IoT and Remote Monitoring: Realtime data tracking allows manufacturers to monitor machine health, productivity, and efficiency from anywhere.

EcoFriendly Packaging: Machines are being optimized to work with recyclable or biodegradable films, aligning with environmental goals.

Enhanced Customization: Modular components make it easier to switch between products and pack types with minimal downtime.

Advanced Sealing Technology: Innovations like ultrasonic sealing or cold sealing allow for gentler handling of heatsensitive products.

The bottom line? Horizontal packing machines aren’t just about wrapping—they’re a part of a smart, scalable production strategy.

Final Thoughts

So, why is a horizontal packing machine the smartest investment for modern packaging? Because it offers speed, flexibility, efficiency, and quality—all in one solution. Whether you’re trying to keep up with growing demand, launch a new product, or simply improve your packaging line’s performance, this machine can take your business to the next level.

英语

英语 西班牙语

西班牙语 简体中文

简体中文