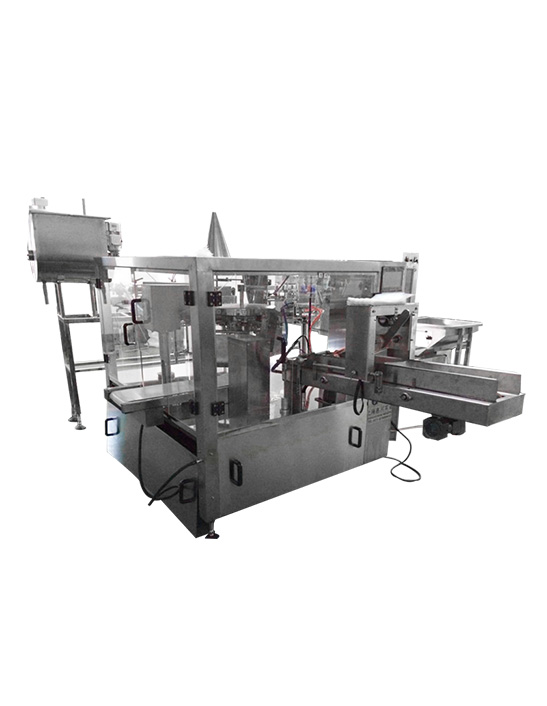

The Face mask packing machine is an automatic device that helps in packaging facial mask cosmetics. The machine also helps in printing the date of manufacture and expiry on the packages.

The

face mask packing machine consists of different parts and components that vary depending on the model and design. Some of the main components include a control system, a conveyor belt and safety systems.

A high speed fully automatic face mask packer will have a bag storage unit that stores packaging bags. When the machine is turned on, it will start automatically picking the bags from this bag storage unit and moving them to the package unit for filling.

Once the bags are filled, they move to the sealing and cutting station where they will be sealed using a heat seal technique. Once they are sealed, the machine will move them to the labeling area where they will be printed with brand names, ingredients and usage instructions.

This machine can pack a variety of masks, including non-woven disposable face masks, surgical masks, N95 masks, 3M masks and single-layer masks.

These masks are used in medical facilities and pharmaceutical labs to avoid germs, dust and other pollutants from entering the human body. The use of these masks has amplified across the globe owing to the increasing airborne diseases.

The global market for face mask packing machines is anticipated to witness robust growth over the forecast period owing to the growing demand for masks. This is primarily due to the rise in airborne diseases and the growing number of hospitals and pharmaceutical laboratories.

英语

英语 西班牙语

西班牙语 简体中文

简体中文